why is there a semiconductor shortage

Since the fall of 2020, the semiconductor shortage has become a global challenge.

Although many people believe that the main cause of the semiconductor shortage is the new coronavirus, its real cause comes from before the new coronavirus disaster. Today, Kotaku Sauce will lead you to predict together how long it will take until the problem is solved based on an in-depth analysis of the causes of the semiconductor shortage.

1. What is a semiconductor

Semiconductor is originally a substance with electrical properties, between the nature of gold, silver, copper and other metals such as conductive "conductor" and rubber, glass and other non-conductive "insulator" between, silicon and other substances and materials belong to this category.

The resistivity of semiconductors varies at different temperatures. At low temperatures, semiconductors hardly conduct electricity, and when the external temperature rises, their ability to conduct electricity increases. In addition, semiconductors that contain almost no impurities do not conduct electricity, while those that contain certain substances conduct electricity more readily. By exploiting these properties of semiconductors, they can be used for electrical control.

In addition, in a broad sense, transistors and ICs (integrated circuits) that use semiconductors for information processing functions can also be called "semiconductors". Therefore, it can be said that semiconductors play the role of the brain of electronic devices.

l Items that use semiconductors

Semiconductors are used not only in industrial equipment, but also in everyday objects, large and small.

Smartphones

Tablet

computers

Digital cameras

TVs

Game consoles

Rice cooker

Refrigerator

Washing machine

Air conditioner

Lighting appliance

Water heater

Automobiles, etc.

Semiconductors are used in general household equipment.

In addition, semiconductors are also essential for ATMs in banks and other financial institutions, medical equipment, social infrastructure such as trains and airplanes, and central equipment for communication infrastructure such as the Internet.

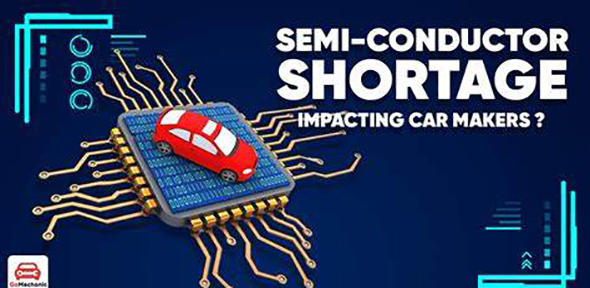

l What happens when there is a shortage of semiconductors?

If there is a shortage of semiconductors, various manufacturers of products that use semiconductors, including those mentioned above, will be unable to produce as planned or will stop production.

In addition, a shortage in the supply of products that use semiconductors will result in the unavailability of desired goods or a significant increase in prices, which will also have a huge impact on the average consumer.

2. The real causes of the global semiconductor shortage

The factors leading to the tight supply and expanding demand for semiconductors are intricate. It is mainly caused by the following reasons.

Economic friction between the US and China

The spread of the new coronavirus outbreak

Supply chain disruptions and soaring transportation costs

Generation of new demand

The impact of the Ukraine crisis

l U.S.-China trade friction

Although the semiconductor shortage is believed to be caused by supply chain disruptions due to the impact of the novel coronavirus and a recovery in demand beyond expectations, it initially stems from the U.S.-China trade frictions in 2019. The U.S. tightened restrictions in order to sanction Chinese companies, resulting in a significant drop in China's semiconductor exports to the U.S. Despite the shift to ordering from Chinese and Taiwanese companies, suppliers of semiconductors are still restricted, resulting in Chinese and Taiwanese semiconductor manufacturers being unable to meet orders. This is a major trigger for the current semiconductor shortage that is still ongoing.

New coronavirus epidemic spreads

The new coronavirus epidemic has changed people's lives and the demand for products using semiconductors has greatly exceeded expectations, which is a major cause of the semiconductor shortage.

There are many kinds of semiconductors, but the shortage is mainly in laptops, smartphones, TVs and cars. With the increase in telecommuting, the demand for laptops has increased dramatically, but the demand for PMICs (power management ICs) installed in laptops has become very tight with the transition to 5G.

In addition, the expanded demand for large-size TVs, etc. due to hive-minded demand has also led to a shortage of DDICs (display driver ICs).

There is also a shortage of MCUs (microcontrollers) that control the operation of automobiles due to increased demand for automobiles to avoid the use of public transportation. Many factories are using the capacity to produce semiconductors for automobiles to produce semiconductors for personal computers, a factor that is having a greater impact on automakers.

l Supply chain disruptions and soaring transportation costs

Due to the expansion of the novel coronavirus outbreak, led by the collective infection of production sites in China, several factories around the world were forced to shut down production. The supply of materials needed to manufacture semiconductors was disrupted globally.

In addition, the novel coronavirus outbreak has led to a shortage of manpower and delays in port operations, which has had a significant impact on the production system for semiconductors.

In addition, with the expansion of the e-commerce market and the global shift to "With coronavirus," the concentration of shipping has led to a global shortage of containers. There was even a shortage of human resources for port operations. As a result, the cost of maritime transportation has fallen into an upward trend during the coronavirus disaster.

l Generation of new demand

In addition to the impact of the new coronavirus epidemic, the generation of new demand was also a factor contributing to the shortage of semiconductors.

As mentioned earlier, originally before the coronavirus disaster, PMICs were in short supply because of the transition from smartphones to 5G. In addition, the continued growth of cloud computing has also increased demand for products used in infrastructure, despite the role played by the new coronavirus epidemic as a catalyst.

In addition, demand is growing significantly in the industrial equipment sector as well as for electric vehicles (EVs) and hybrid electric vehicles (HEVs) to achieve a decarbonized society. This is because EVs and HEVs will carry several times more semiconductors compared to fuel vehicles.

In addition to this, demand for bitcoin mining has expanded the demand for graphics boards, etc., which has also had a considerable impact on the semiconductor shortage.

l Impact of the Ukraine Crisis

The concern is that the crisis in Ukraine may exacerbate this semiconductor shortage. Rare gases used to make semiconductors, such as neon, krypton and xenon, and some rare metals come from Russia and Ukraine, so the impact on the supply chain is a concern.

Neon gases, in particular, are responsible for 70% of the world's demand in Ukraine. In fact, in the past, when Russia annexed Crimea in 2014, the price of neon gas had spiked about six times. Moreover, the supply chain of neon gas between Russia and Ukraine was cut off due to Russia's invasion of Ukraine.

However, given the supply risk in Ukraine, the companies concerned had stocked up prior to the Russian invasion, so the impact has not yet been felt. However, the impact of a long-term military invasion on the supply chain will remain a concern.

3. How much longer will the semiconductor shortage last? When will it be solved?

How long will the semiconductor shortage, which has had a huge impact on manufacturing and other industries, continue? Most professional organizations and semiconductor manufacturers expect the semiconductor shortage to moderate starting in 2022.

l Moderation is expected to start in 2022

According to Gartner's semiconductor market forecast released on May 11, 2021, companies are expected to move toward a moderation starting in the second quarter of 2022.

The positive factor is that many semiconductor manufacturers have indicated that they will add production lines. In addition to having production lines running from the summer of 2022, repeat orders from trading companies wary of semiconductor shortages will arrive around spring 2022.

However, we are also concerned about the continued growth in global demand for semiconductors and the risk that the spread of new coronavirus infections due to the emergence of new mutant strains could affect production systems and lead to supply chain disruptions. Although intermittent, it is undeniable that the semiconductor shortage is likely to continue in 2022.

l NVIDIA and AMD's Perspective

Due to severe power shortages caused by the effects of the cold snap in February 2021, semiconductor factories in Texas that use large amounts of electricity were forced to temporarily stop their businesses. The production shutdown affected by the cold snap also exacerbated the semiconductor shortage.

Nevertheless, major global semiconductor manufacturers said they expect the semiconductor shortage to be solved in 2022. As for the timing of the semiconductor shortage, AMD in the U.S. predicts the second half of 2022, and NVIDIA in the U.S. and ARM in the U.K. also predict the second half of 2022.

The Worrying Semiconductor "2024 Problem"

So far, we have been concerned about the semiconductor shortage, and we are also worried about the "2024 problem" of oversupply of semiconductors in 2024. The semiconductor shortage has driven the U.S. and China to expand capacity by building giant semiconductor factories, and excessive capital spending could lead to an oversupply of semiconductors in 2024.

Both the U.S. and China aim to create a unified supply chain at home. In the U.S., trade frictions with China have switched the ordering party to companies in China and Taiwan, and since demand cannot be met, measures have been taken to increase the domestic production base through government grants.

The global shortage of semiconductors has allowed semiconductor manufacturers to raise prices, which will continue to soar through 2022. However, due to oversupply, there has been a movement centered on large manufacturers on the purchasing side to demand price cuts, and prices are expected to fall. In addition, as China hopes to expand its global market share by investing in subsidies, it is adopting a sales strategy without regard to profitability, which may also be one of the reasons for lower semiconductor prices.

On the other hand, there is also a view that there is no concern about oversupply in terms of the increase in the number of products carrying semiconductors. Because in the future, the increasing need for semiconductors will be multifaceted areas, including the popularity of electric vehicles and ADAS (Advanced Driver Assistance Systems), the development of autonomous driving technology, the popularity of IoT-connected IoT devices, or the popularity of industrial robots and collaborative robots in factories.

Summary

The semiconductor shortage stems from multiple factors such as the trade friction between the US and China and the new coronavirus outbreak. In addition, the rapid recovery from the decline in demand due to the expansion of new coronavirus infections to the new demand generated by the new coronavirus epidemic is also a major reason.

However, since the shortage of semiconductors is expected to be resolved within 2022, companies that produce related products are expected to have stable plant operations.